Master The 3 4 5 Rule Carpentry: A Hands-On Guide For Craftsmen

Let me tell ya somethin’, fellas, the 3 4 5 rule in carpentry ain’t just a fancy phrase thrown around by professionals. It’s the backbone of precision work and a game-changer for anyone serious about building stuff that lasts. Imagine this: you’re out there on a job site, trying to square up a corner, and suddenly you’re second-guessing yourself. Well, not anymore. The 3 4 5 rule’s got your back, and it’s as simple as pie.

Now, before we dive deep into the nitty-gritty, lemme break it down for you real quick. The 3 4 5 rule in carpentry is all about creating perfect right angles without breaking a sweat. Think of it like a shortcut handed down from the gods of construction themselves. If you’re a newbie or even a seasoned pro looking to sharpen your skills, this rule is your golden ticket to accuracy. Stick around, and I’ll show you how it works like a charm.

Here’s the deal: carpentry is both an art and a science. You need creativity, but you also need precision. That’s where the 3 4 5 rule comes in. It’s not rocket science, but it’s damn close to being foolproof. So, if you’re ready to level up your game and make every project spot-on, let’s get started. Trust me, you’re gonna love this.

Read also:Jessica Tarlovs Transparent Bikini A Bold Fashion Statement Thats Taking The World By Storm

What is the 3 4 5 Rule in Carpentry?

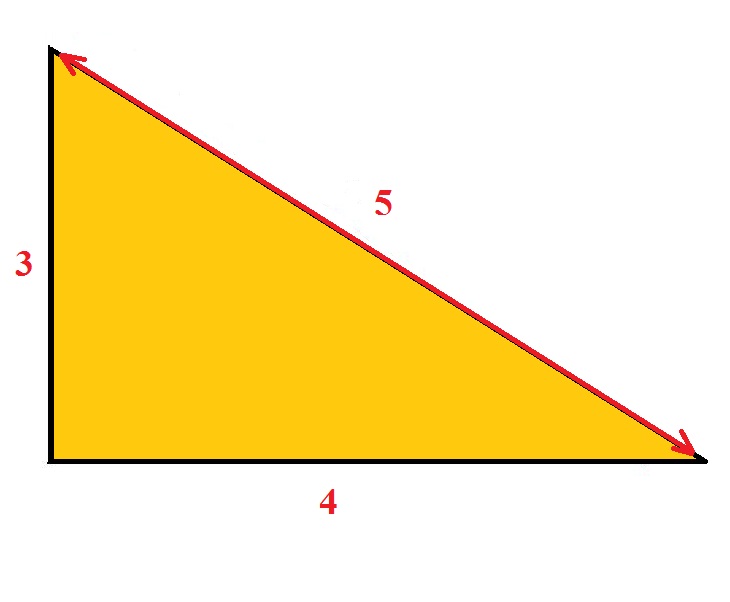

The 3 4 5 rule in carpentry is like the secret sauce of geometry for builders. It’s based on the Pythagorean theorem, which says that in a right triangle, the square of the hypotenuse equals the sum of the squares of the other two sides. Now, don’t let that math jargon scare you. In carpentry terms, it means if you measure 3 units along one side, 4 units along the other, and 5 units diagonally, you’ve got yourself a perfect right angle. Easy, right?

Let’s break it down:

- 3 units along one side

- 4 units along the perpendicular side

- 5 units diagonally

Boom! You’ve just squared up your corner. No fancy tools, no complicated calculations, just good old-fashioned math that works every time.

Why the 3 4 5 Rule is Essential for Carpenters

Listen up, folks. The 3 4 5 rule isn’t just a cool trick; it’s essential. Why? Because it ensures accuracy, and accuracy is the name of the game in carpentry. Whether you’re building a deck, framing a wall, or laying out a foundation, getting those angles right is critical. One wrong measurement, and you’re looking at a costly redo. Nobody’s got time for that.

Here’s why the 3 4 5 rule is so important:

- It eliminates guesswork and ensures perfect squares every time.

- It’s quick and easy to apply on the job site.

- It works for large-scale projects as well as small ones.

- It’s reliable and consistent, no matter the conditions.

So, if you want to be the go-to guy on the job site, mastering this rule is a must. Trust me, your coworkers will be impressed, and your clients will be thrilled.

Read also:How To Remotely Access Raspberry Pi Ssh A Beginners Guide For Tinkerers

How to Apply the 3 4 5 Rule in Real Projects

Talkin’ theory’s all fine and dandy, but let’s get practical. How do you actually use the 3 4 5 rule in real-life carpentry projects? It’s simpler than you think. Whether you’re working on a small shed or a massive commercial building, the process is the same.

Step-by-Step Guide

Here’s a quick step-by-step guide to applying the 3 4 5 rule:

- Start by marking one side of the corner as 3 units.

- Mark the perpendicular side as 4 units.

- Measure diagonally between the two marks. It should be exactly 5 units.

- If it’s not, adjust your layout until it is.

Simple, right? And the beauty of it is, you can scale this up or down depending on the size of your project. For larger projects, you can use 6-8-10 or even 9-12-15 for the same effect. It’s all about proportions.

Common Mistakes to Avoid

Now, here’s the thing: even with a foolproof rule like this, mistakes can happen. The key is knowing what to watch out for. Here are some common pitfalls to avoid:

- Not measuring accurately. Even a tiny error can throw off your entire layout.

- Using the wrong units. Make sure everyone on the job site is on the same page about measurements.

- Not double-checking. Always verify your measurements before committing to anything permanent.

Remember, the 3 4 5 rule is only as good as your attention to detail. Stay sharp, and you’ll be golden.

Tools You’ll Need for the 3 4 5 Rule

You don’t need a lot of fancy gear to use the 3 4 5 rule, but having the right tools makes all the difference. Here’s what you’ll need:

- A good tape measure. Preferably one that’s long enough for your project.

- A marking tool, like a pencil or chalk line.

- A straight edge or level to ensure your marks are accurate.

That’s it. No expensive gadgets, no complicated setups. Just good old-fashioned tools that get the job done.

Advanced Techniques with the 3 4 5 Rule

Once you’ve got the basics down, it’s time to level up. The 3 4 5 rule isn’t just for simple corners; it can be used for more complex layouts too. For example, if you’re working on a circular structure, you can use the rule to ensure your arcs are perfectly aligned. Or, if you’re dealing with irregular shapes, the rule can help you find the right angles to make everything fit together seamlessly.

Using the Rule for Diagonal Checks

One advanced technique is using the 3 4 5 rule for diagonal checks. This is especially useful for large structures where ensuring all corners are square is crucial. By measuring diagonally across opposite corners, you can quickly identify any discrepancies and make adjustments before it’s too late.

Case Studies: Real-World Applications

Let’s look at some real-world examples of how the 3 4 5 rule has been used successfully in carpentry projects. Take, for instance, the construction of a custom home in Colorado. The builders used the rule to ensure every corner of the house was perfectly square, resulting in a structure that not only looks great but also stands the test of time.

Another example is a commercial building in Texas. The project required precise alignment of all walls and floors. By applying the 3 4 5 rule consistently throughout the build, the team was able to complete the project on time and within budget, with zero structural issues.

Tips and Tricks for Mastering the 3 4 5 Rule

Here are a few tips to help you master the 3 4 5 rule:

- Practice on smaller projects first to build confidence.

- Use the rule consistently to develop muscle memory.

- Teach others on your team so everyone’s on the same page.

Remember, the more you use the rule, the more natural it becomes. Before you know it, you’ll be squaring up corners like a pro without even thinking about it.

Conclusion: Embrace the 3 4 5 Rule

So, there you have it, folks. The 3 4 5 rule in carpentry is your secret weapon for precision and accuracy. Whether you’re a newbie or a seasoned pro, mastering this rule will take your skills to the next level. Don’t just take my word for it; try it out on your next project and see the difference it makes.

Now, here’s the deal: if you found this article helpful, do me a solid and share it with your carpentry buddies. The more people who know about the 3 4 5 rule, the better. And if you’ve got any questions or tips of your own, drop them in the comments below. Let’s keep the conversation going!

Table of Contents

- Master the 3 4 5 Rule Carpentry: A Hands-On Guide for Craftsmen

- What is the 3 4 5 Rule in Carpentry?

- Why the 3 4 5 Rule is Essential for Carpenters

- How to Apply the 3 4 5 Rule in Real Projects

- Common Mistakes to Avoid

- Tools You’ll Need for the 3 4 5 Rule

- Advanced Techniques with the 3 4 5 Rule

- Case Studies: Real-World Applications

- Tips and Tricks for Mastering the 3 4 5 Rule

- Conclusion: Embrace the 3 4 5 Rule